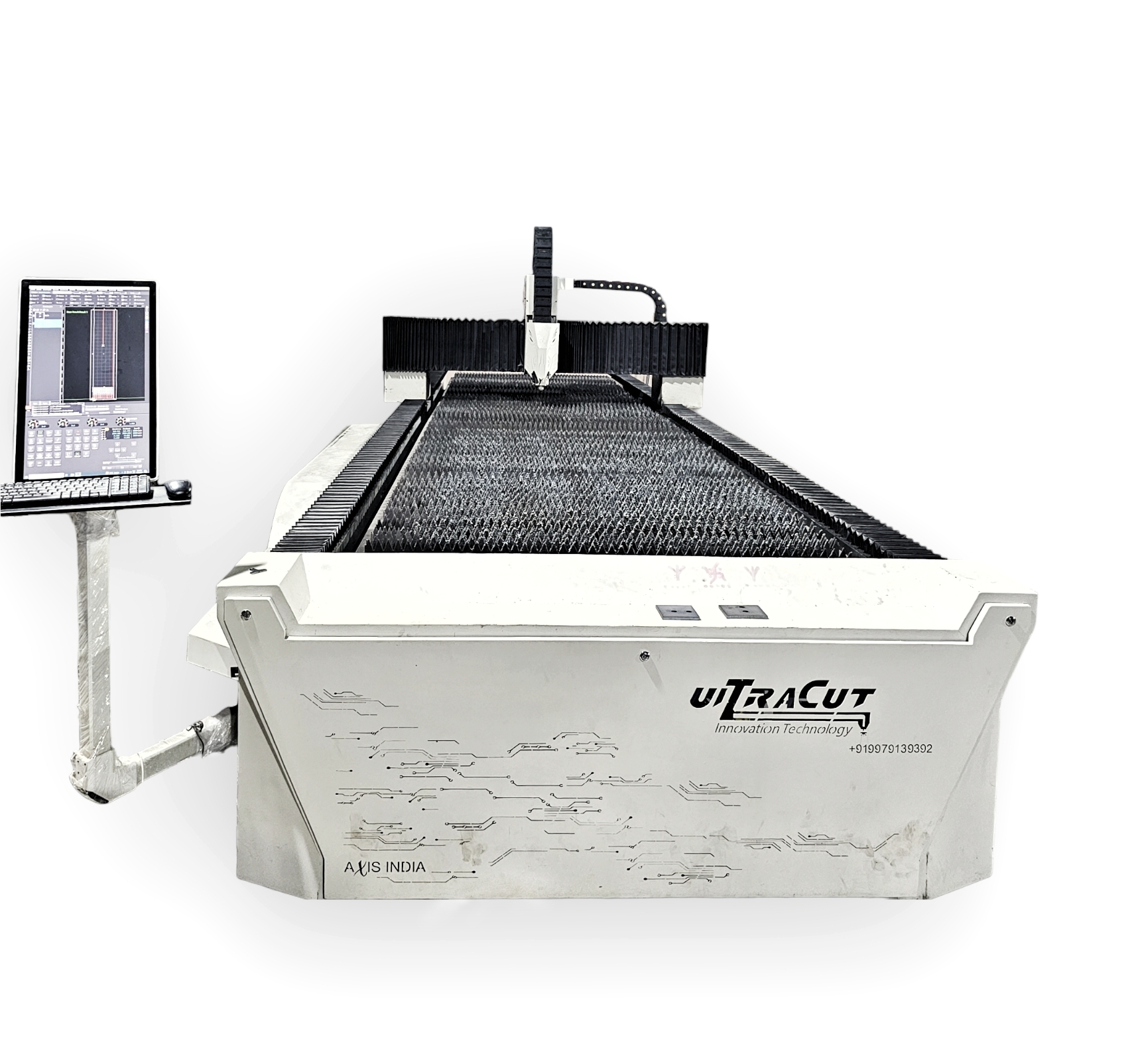

High Performance Automatic Fiber Laser Metal Cutting Machine

Price 1900000 INR/ Unit

High Performance Automatic Fiber Laser Metal Cutting Machine Specification

- Power

- 1000W/2000W/3000W/4000W/6000W/8000W (optional)

- Working Area

- 1500 mm x 3000 mm

- Technology

- Fiber Laser Cutting Technology

- Phase

- Three Phase

- Usage & Applications

- Sheet Metal Cutting, Manufacturing, Engineering, Automobile, Aerospace, Electrical Appliances

- Product Type

- Metal Cutting Machine

- Laser Type

- Fiber Laser

- Material

- Cutting Thickness

- 0.5 mm 25 mm (depends on material and laser power)

- Cutting Area

- 3000 mm x 1500 mm (customizable)

- Cutting Speed

- 0-40 m/min (material and power dependent)

- CNC Or Not

- Yes

- Computerized

- Yes

- Automatic Grade

- Automatic

- Cooling Mode

- Water Cooling

- Control Software

- CypCut

- Graphic Format Supported

- DXF, DWG, PLT, AI

- Control System

- CNC (Computerized Numerical Control)

- Voltage

- 380V / 50Hz / 60Hz

- Weight (kg)

- 3200 kg (varies by model)

- Dimension (L*W*H)

- 4600 mm x 2300 mm x 1800 mm (approx.)

- Capacity

- High Production, 24/7 Operation

- Feature

- High Precision, Low Energy Consumption, Stable Operation

- Color

- White & Blue (customized options available)

- Drive System

- Precision Rack and Pinion with Servo Motor

- Power Consumption

- 8-15 kW (model dependent)

- Repositioning Accuracy

- 0.02 mm

- Noise Level

- 65dB

- Operation Interface

- Touch Screen Display

- Positioning Accuracy

- 0.03 mm

- Maximum Empty Running Speed

- 120 m/min

- Focus Mode

- Automatic or Manual (According to Configuration)

- Safety System

- Full Enclosure with Protective Glass (as per spec)

- Support Service

- Online & Field Installation, Commissioning, Training

- Operating Software Language

- Multi-language Supported

- Transmission Type

- Dual-side Gear and Rack Drive

- Assist Gas

- Oxygen, Nitrogen, Air

- Working Temperature

- 5-40C

- Table Design

- Exchange Platform (Optional)

- Lens Type

- Imported Focusing Lens

- Minimum Line Width

- 0.1 mm

- Laser Wavelength

- 1070 10 nm

- Environment Humidity

- 5-95% Non-Condensing

About High Performance Automatic Fiber Laser Metal Cutting Machine

Laser Head Brand-Raytools

Guiderail Brand-HIWIN

Machinery Test Report-Provided

Video outgoing-inspection-Provided

Warranty of core components 2 years,

Core Components-laser generator

Laser power-3000W

Laser source-Max

Control system-Weihong Control System

Driving system-Japan Servo Motor

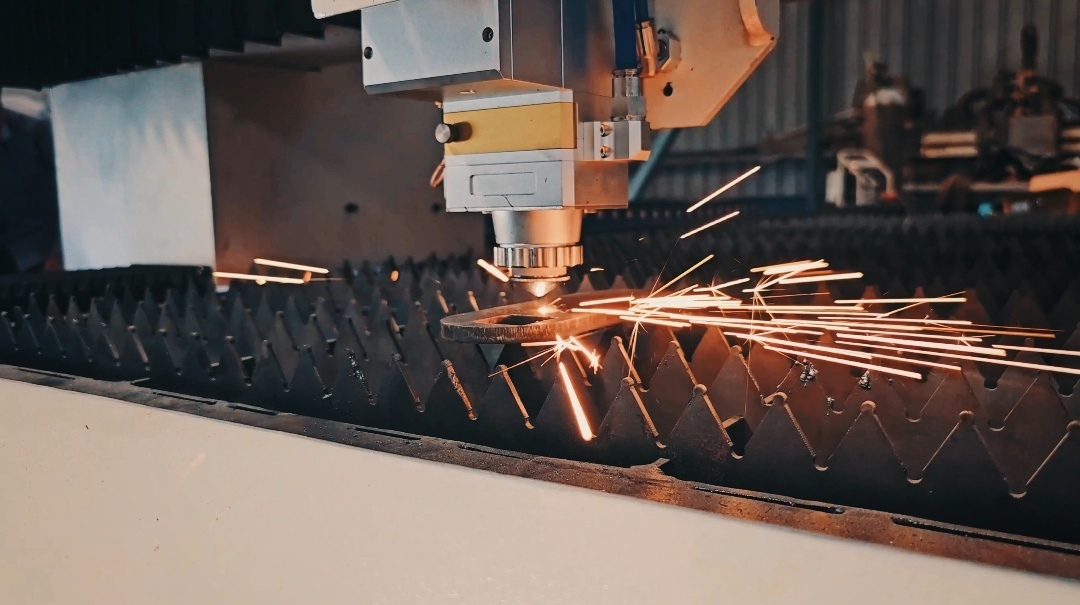

Characteristics of 1000w fiber metal cutting equipment

1.Great Performance

Identical cutting quality on any cutting point is realized through fiber transmission.

2.High Efficiency

The rapid cutting speed is two times higher than that of CO2 laser machine.Its use-cost is low.

3.Low Consumption of Gas

Laser cutting does not make any gas because of the specific cutting technology on steel plate.

4.Low Consumption of Energy

It is environment-protecting and energy-saving.Its power consumption is reduced by 20%-30% compared with that of CO2 laser machine.

5.Maintenance-free

Reflecting lens is not needed for fiber transmission.Much time is saved when optical path is adjusted.It is maintenance-free.

Unmatched Precision & Speed

Designed for high-precision industrial tasks, this fiber laser cutter achieves a minimum line width of just 0.1 mm while supporting cutting speeds up to 40 m/min, and an empty running speed of 120 m/min. The advanced CNC control and imported focusing lens ensure exact results across jobs, making it ideal for demanding engineering, aerospace, and automotive applications.

Versatility Across Materials & Applications

Our fiber laser cutting machine easily processes carbon steel, stainless steel, aluminum, brass, and copper, with a cutting thickness capacity of 0.525 mm depending on laser power. Widely used in factories, workshops, and production lines, it handles complex tasks in electrical appliance manufacture, aerospace components, and metal fabrication.

User-Friendly and Safe Operation

Equipped with a multi-language touch screen display, fully enclosed body, and safety protective glass, the machine ensures operator safety while maintaining ease of use. Automated and manual focus options, along with software like CypCut, offer control and flexibility to operators of all skill levels in various working environments.

FAQs of High Performance Automatic Fiber Laser Metal Cutting Machine:

Q: How does the automatic fiber laser metal cutting machine ensure high cutting precision?

A: The machine utilizes precision rack and pinion drive with servo motors, dual-side gear and rack transmission, and imported focusing lenses. Its advanced CNC system, combined with a robust mechanical structure, achieves a remarkable positioning accuracy of 0.03 mm and repositioning accuracy of 0.02 mm, ensuring high-precision cutting for intricate designs.Q: What materials and thicknesses can this fiber laser cutter process?

A: It can cut carbon steel, stainless steel, aluminum, brass, copper, and other metals. The cutting thickness ranges from 0.5 mm up to 25 mm, depending on the metal type and power configuration (1000W8000W options available).Q: When should I use oxygen, nitrogen, or air as assist gases?

A: Oxygen is generally used for carbon steel to enhance cutting speed and maintain edge quality. Nitrogen is ideal for cutting stainless steel, aluminum, and other non-ferrous metals to avoid oxidation and discoloration. Air can be used for cost-effective cutting of thinner materials when high purity is not essential.Q: Where can this fiber laser cutting machine be installed and operated?

A: Designed for industrial environments, it can be installed in manufacturing plants, workshops, or fabrication units. The system operates optimally under temperatures of 540C and humidity levels of 595% (non-condensing), and its noise level ( 65dB) allows use in both large spaces and urban industrial settings.Q: What is the process for machine installation, commissioning, and training?

A: Upon purchase, our team provides complete installation and commissioning of the equipment onsite. We offer comprehensive operator training, both online and in-person, to ensure seamless integration into your production workflow and proper use of the control software (CypCut).Q: How does the exchange platform design benefit high-volume production?

A: The optional exchange platform allows for loading and unloading of materials while the machine is cutting, minimizing downtime and maximizing productivity. This design is especially beneficial for continuous, high-volume manufacturing operations that demand speed and efficiency.Q: What are the main benefits of using this automatic fiber laser cutting machine?

A: Key advantages include exceptional precision, stable operation, low energy consumption, multi-material capability, user-friendly interface, high production capacity (24/7 operation), extensive safety features, customizable configurations, and responsive local service support throughout India.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Fiber Laser Cutting Machine Category

CNC Metal Laser Cutting Machine

Price 1700000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Product Type : CNC Metal Laser Cutting Machine

Automatic Grade : Automatic

Computerized : Yes

Laser Type : Fiber Laser

Pro-Arc Mild Steel CNC Fiber Laser Cutting Machine

Price 1500000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Product Type : metal

Automatic Grade : Automatic

Computerized : Yes

Laser Type : Fiber Laser

fiber metal laser cutting machine

Price 2100000 INR / Unit

Minimum Order Quantity : 1 Unit

Product Type : metal

Automatic Grade : Automatic

Computerized : Yes

Laser Type : Fiber Laser

Three Phase Cnc Fiber Laser Cutting Machine

Price 1700000 INR / Piece

Minimum Order Quantity : 1 Piece

Product Type : Fiber Laser Cutting Machine

Automatic Grade : Automatic

Computerized : No

Laser Type : Fiber Laser

Send Inquiry

Send Inquiry

Call Me Free

Call Me Free