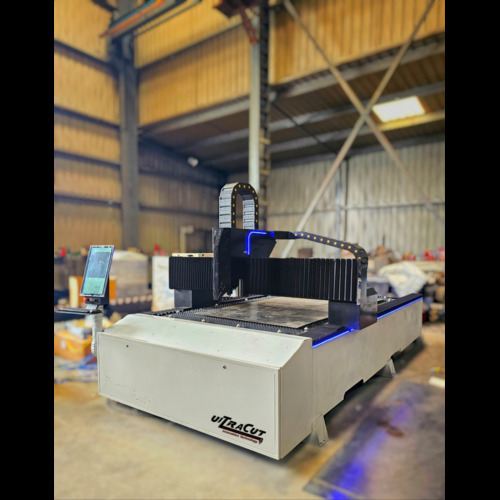

1000 Watt CNC Laser Metal Cutting Machine

Price 2000000.0 INR/ Unit

1000 Watt CNC Laser Metal Cutting Machine Specification

- Product Type

- metal

- Laser Type

- Fiber Laser

- Cutting Thickness

- 0-12 Millimeter (mm)

- Cutting Area

- 1550*3100 Square Millimeter (mm2)

- Cutting Speed

- 0-100 m/m

- CNC Or Not

- CNC

- Computerized

- Yes

- Automatic Grade

- Automatic

- Cooling Mode

- Water Cooling

- Control Software

- Weihong

- Graphic Format Supported

- DXF

- Control System

- Frequency Speed Control

- Voltage

- 380 Volt (v)

- Weight (kg)

- 3500 Gram (g)

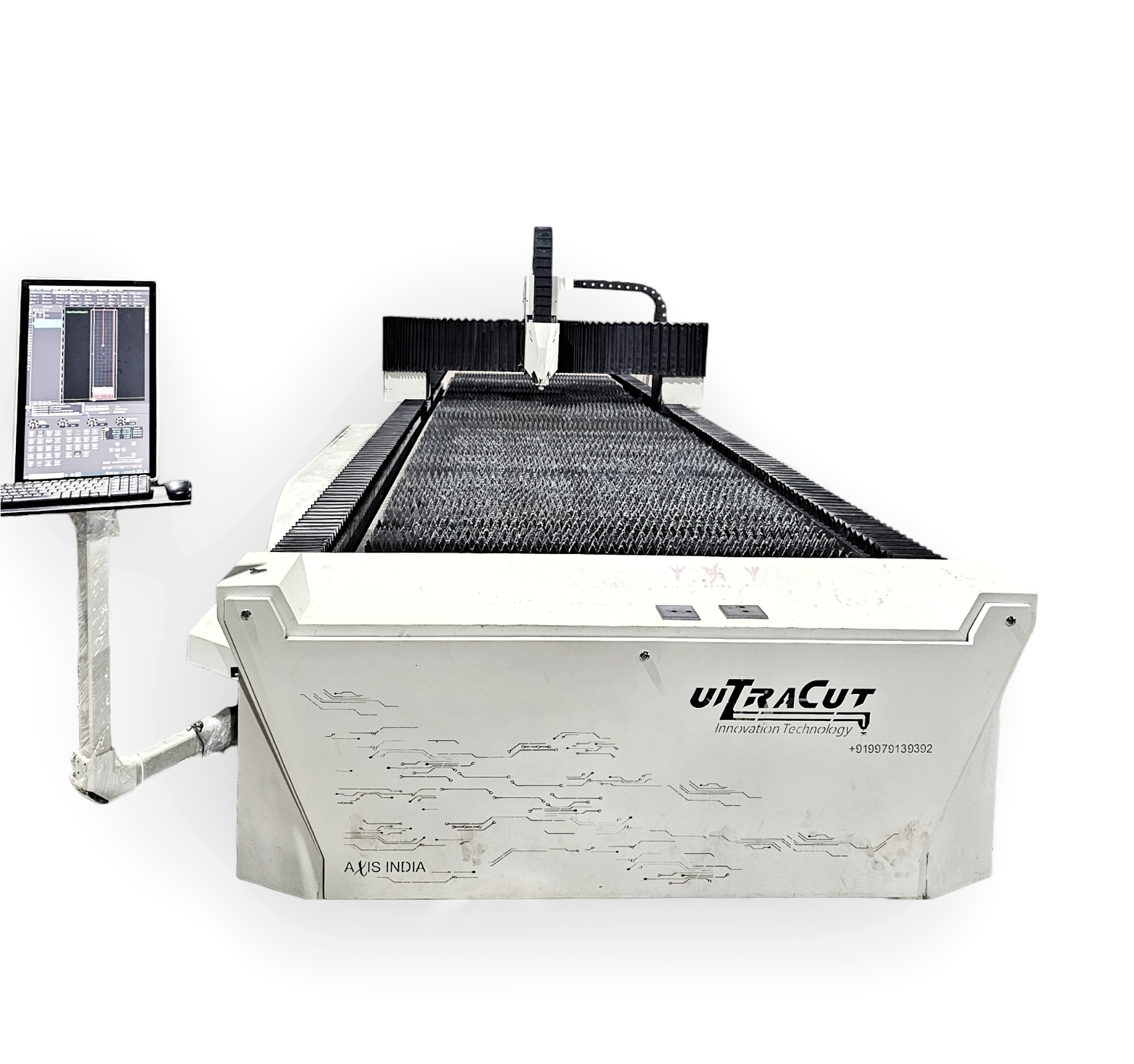

- Dimension (L*W*H)

- 170*92*72 Inch (in)

- Feature

- Lower Energy Consumption, High Efficiency

- Color

- Green

- Warranty

- 2 Years

1000 Watt CNC Laser Metal Cutting Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- FOB Port

- Vadodara

- Payment Terms

- Cash in Advance (CID), Cheque

- Supply Ability

- 1 Unit Per Month

- Delivery Time

- 45 Days

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Wooden Box Packaging

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- All India

About 1000 Watt CNC Laser Metal Cutting Machine

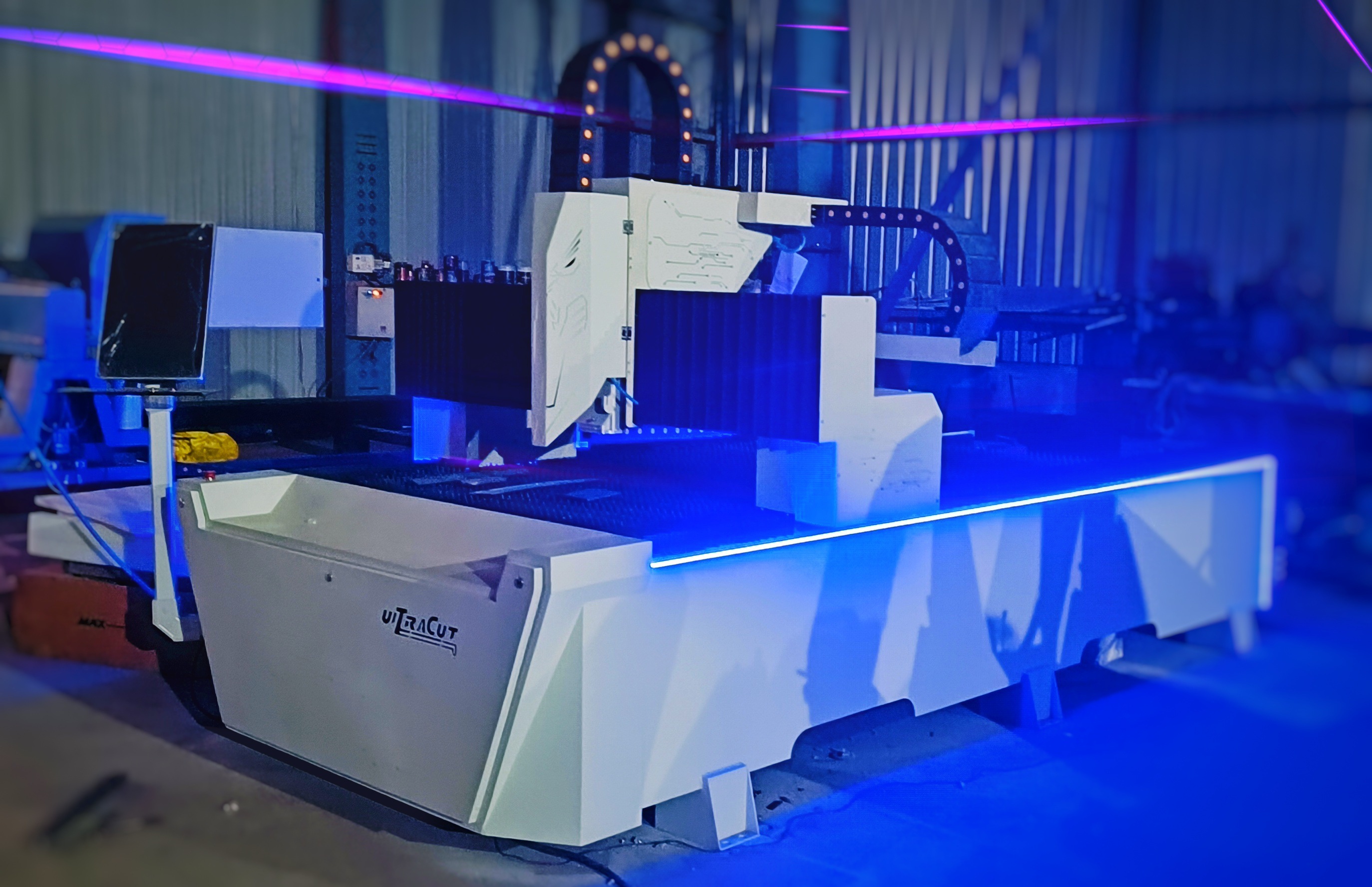

1. High-performance laser device associated with stable operation system enables optimal cutting effects.

2. Perfect cooling, lubrication and dedusting systems ensure stable, efficient and durable performance of the

whole machine.

3. Single countertop make plates loading and unloading available during cutting, which improves the

processing eficiency.

4. Large-size closed enclosure improves dedusting effects and avoids optical pollution.

5. Automatic height-adjustment performance keeps constant focal length and stable cutting quality.

6. Gantry structure and inblock aluminum cast cross beam make the device highly rigid, stable and antiknock.

7. It could ut mental in various materials and realize excellent and stable cutting effects.

Characteristics of 1000w fiber metal cutting equipment

1.Great Performance

Identical cutting quality on any cutting point is realized through fiber transmission.

2.High Efficiency

The rapid cutting speed is two times higher than that of CO2 laser machine.Its use-cost is low.

3.Low Consumption of Gas

Laser cutting does not make any gas because of the specific cutting technology on steel plate.

4.Low Consumption of Energy

It is environment-protecting and energy-saving.Its power consumption is reduced by 20%-30% compared with that of CO2 laser machine.

5.Maintenance-free

High-Efficiency Metal Cutting

Engineered for optimal productivity, this 1000 Watt CNC Laser Metal Cutting Machine achieves fast, precise results while consuming less energy. The fiber laser ensures consistent high-quality cutting on a variety of metals up to 12 mm thick, making it suitable for manufacturing and fabrication sectors that demand efficiency and accuracy.

Seamless Automation and Control

With its automatic operation grade and Weihong software, operators enjoy a streamlined workflow and easy graphics integration. The computerized CNC system paired with frequency speed control allows for detailed customization, improving both versatility and reliability during large or complex production runs.

FAQs of 1000 Watt CNC Laser Metal Cutting Machine:

Q: How does the 1000 Watt CNC Laser Metal Cutting Machine achieve high efficiency and lower energy consumption?

A: The machine utilizes advanced fiber laser technology, allowing for precise energy delivery and minimal heat loss. Its frequency speed control and automatic operation combine to minimize wasted power and maximize output speed and accuracy, delivering efficient cutting with reduced electricity usage.Q: What materials and thicknesses can this laser cutting machine process?

A: It is engineered to cut metal sheets with a thickness range from 0 up to 12 millimeters. The powerful 1000-watt fiber laser performs exceptionally on various metals, including steel, stainless steel, and aluminum.Q: When is this CNC laser cutting machine most beneficial for my operations?

A: This machine is ideal when your production requires high-speed, high-precision metal cutting, especially for industrial-scale tasks. It is most useful in manufacturing environments where consistent quality, repeatability, and energy efficiency are essential.Q: Where can the machine be installed, and what space requirements should be considered?

A: The machine is suitable for industrial or workshop environments and requires installation space according to its dimensions of 170 x 92 x 72 inches. Ensure adequate room for the cutting area (1550 x 3100 mm) and access for water cooling and maintenance.Q: What is the process for operating this CNC laser cutter?

A: Operators load the DXF-cutting files via the Weihong control software, configure cutting parameters, and monitor the process through the computerized control system. The automatic and CNC integration ensures straightforward setup, execution, and adjustment for different projects.Q: How does the machines water cooling system benefit operation?

A: The water cooling system effectively maintains optimal operating temperatures for the laser source and vital components, enhancing the machines performance stability, extending its lifespan, and reducing downtime due to overheating.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Laser Metal Cutting Machine Category

Laser Cnc 3000W Laser Sheet Metal Laser Fiber Cutting Machine

Price 1500000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Computerized : Yes

CNC Or Not : CNC

Cooling Mode : Water Cooling

Automatic Grade : Automatic

Heavy-Duty 3000W Fiber Laser Cutting Machine for Steel Fabrication

Price 1500000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Computerized : Yes

CNC Or Not : CNC

Cooling Mode : Water Cooling

Automatic Grade : Automatic

Laser Cutting Machine

Price 1000000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Computerized : Yes

CNC Or Not : CNC

Cooling Mode : Water Cooling

Automatic Grade : Automatic

Laser Cutting Machine 1500KW

Price 2000000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Computerized : Yes

CNC Or Not : CNC

Cooling Mode : Water Cooling

Automatic Grade : Automatic

Send Inquiry

Send Inquiry